Do you want more information and pricing?

We will contact you

Economic and efficient benefits with BWC

- Economic and efficient benefits with BWC

Cost-reducing and efficient solutions for prefabrication of building elements.

Efficiency through repetition

- Planning

- Standardization

- Prefabrication

- Assembly

- Deviations and reduction of complaints

= economic improvement at all levels.

Balcony established when the outer wall is finished.

Provides:

- Scaffolding up until the climate wall is established

- Lower costs for cranes

- Reduced construction time

- Banisters can be mounted on the ground - safety benefits, lower installation costs

- Thinner balcony elements, less concrete

- Adjustment possibilities during installation

- Waterproof

- Impact sound reduction

- Good overall economy for the project

Utkragede balkonger

Benefits cantilevered balconies:

- Thin balconies = over 50% weight reduction= Less concrete = less CO2 footprint

- Reduced crane- and transportcosts

- Time saving

- Waterproof

- Thermal bridge breaker

- Will be established when the outerwall is finished

| Article no | Description | Picture |

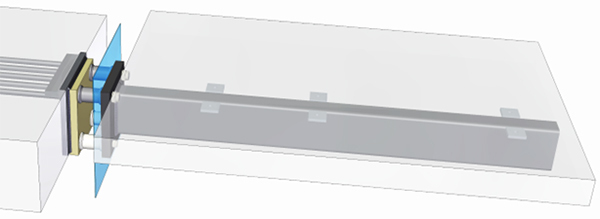

| BWC 40 U-H | The unit consists of a steel back plate, bolt group, insulation layer and a rubber membrane that prevents water ingress. |  |

Cantilevered balconies

| BWC U-H in casted slabs. The unit is welded to a steel plate with horizontal reinforcement rods. |  |

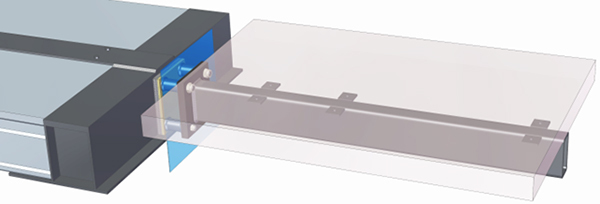

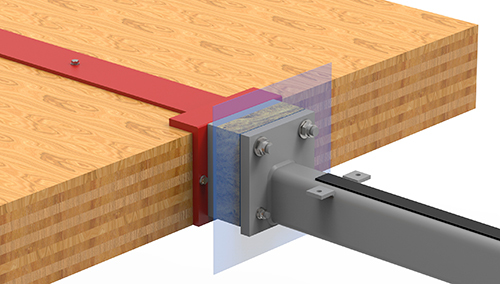

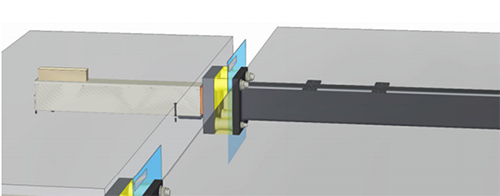

| Combine the hollow core and a cantilevered BWC solution. Here, a RHS profile is placed on the outside of the hollow core, to which our units are welded. Here you can also see that there is a steel band on top of the hollow core. . |  |

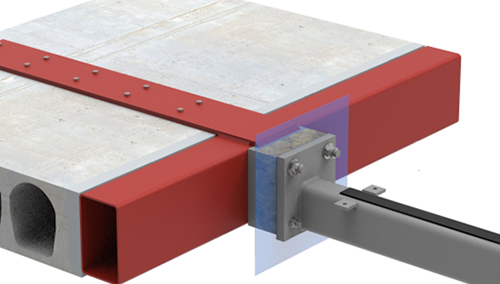

| HSQ, Deltabeam towards the end of the hollow core The picture shows an installation using a HSQ beam. |  |

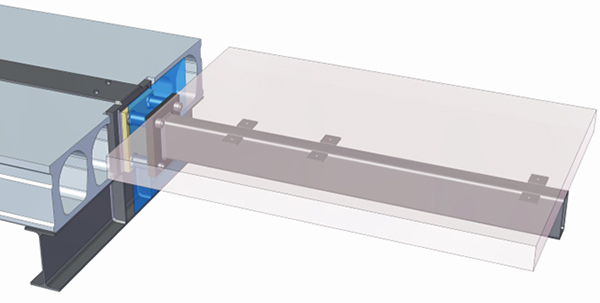

| Combine the hollow core and a cantilevered BWC solution. If the hollow core is on an IPE or similar profile, we use this. Here you can also see that there is a steel band on top of the hollow core. |  |

Combine the solid wood deck and a cantilevered BWC solution. |  |

| BWC U-H with recess box in the casted slab. The unit will be delivered with a horizontal profile. |  |