Do you want more information and pricing?

Instructions cantilevered balconies

- Products→

- Balcony connections→

- Instructions cantilevered balconies

Moment connections

BWC 40 U-H is our system when designing with cantilevered balconies, and these take both shear and tensile forces (See Memo 750 Guidance BWC cantilever beam).

What distinguishes our solutions most from other traditional thermal bridge breakers is that our solutions enable the establishment of the balcony when the outer wall is finished.

A cold thermal bridge is actually a heat bridge, because heat is led out through the "bridge". To reduce heat loss,

it is important to have as few thermal bridges as possible in an energy-efficient building.

Another aspect that is becoming more and more relevant is that our connectors invite the reuse of concrete elements.

For more information see Memo 750

Cantilevered balconies

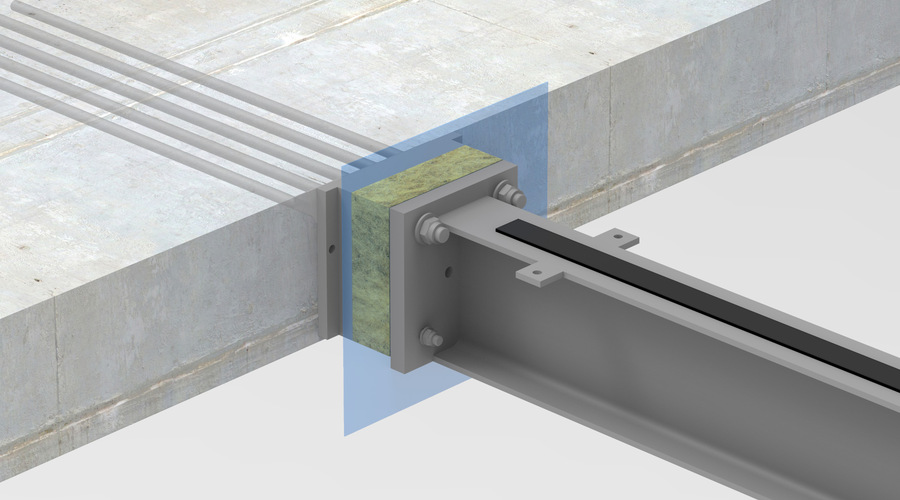

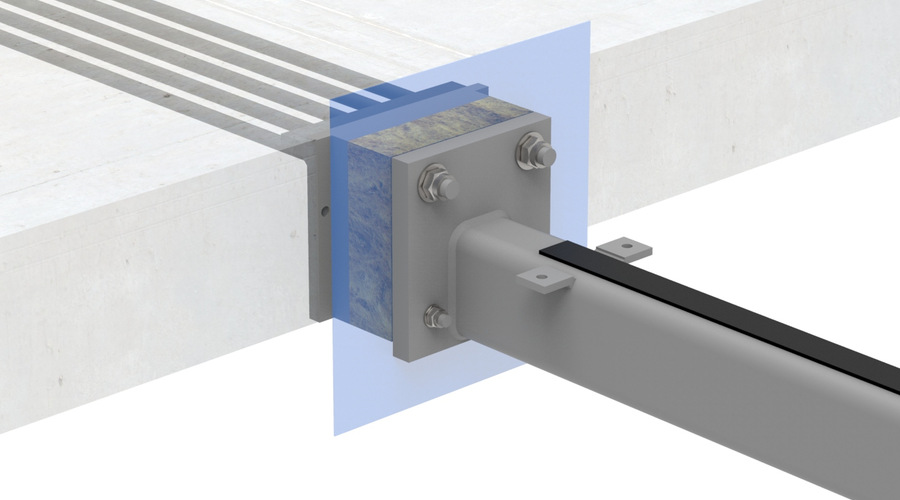

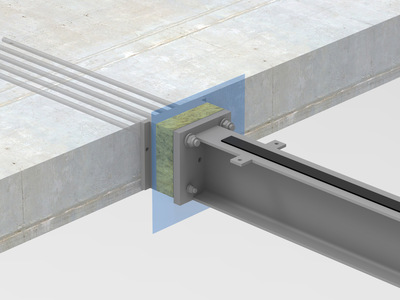

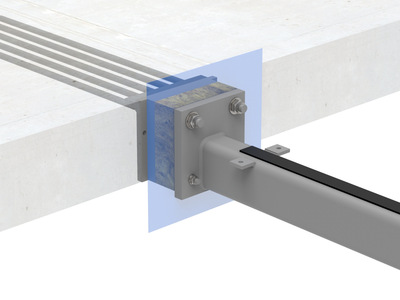

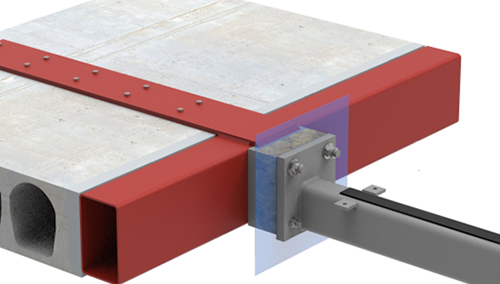

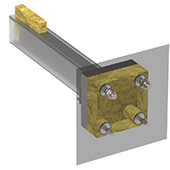

| BWC 40 U-H System that is welded to a steel plate, RHS profile, UPE, HSQ, Deltabeam etc. |  |

| BWC U-H in casted slabs. The unit is welded to a steel plate with horizontal reinforcement rods. |  |

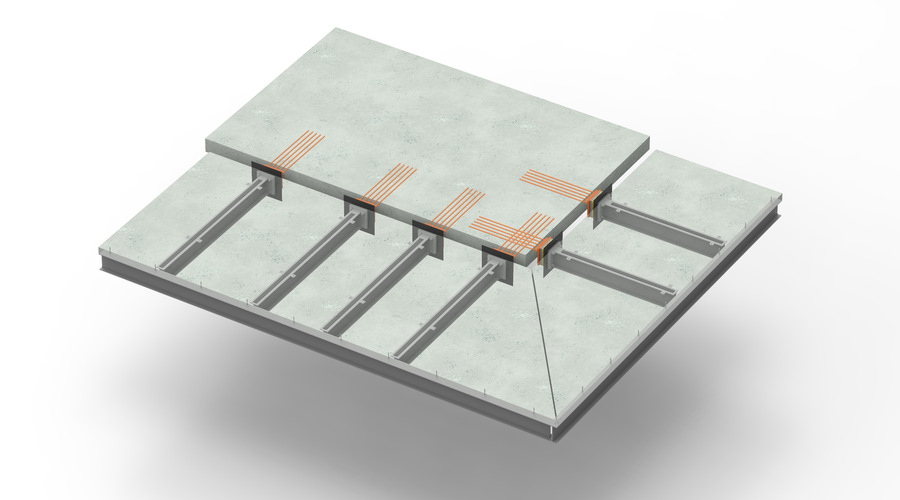

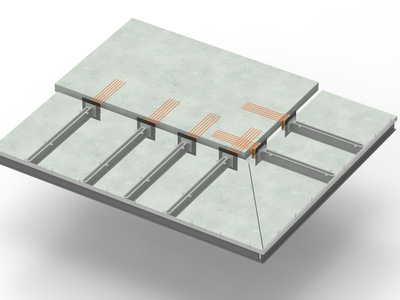

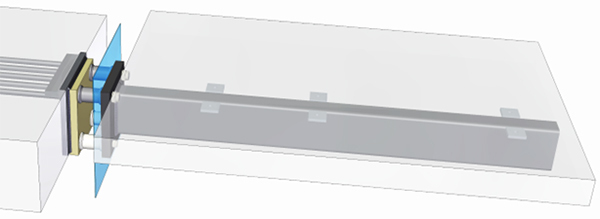

| Combine the hollow core and a cantilevered BWC solution. Here, a RHS profile is placed on the outside of the hollow core, to which our units are welded. Here you can also see that there is a steel band on top of the hollow core. . |  |

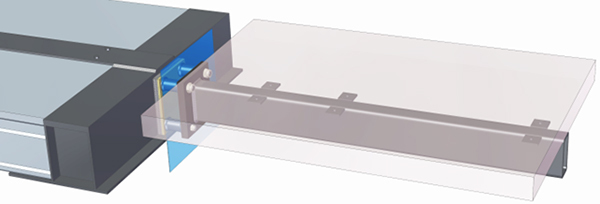

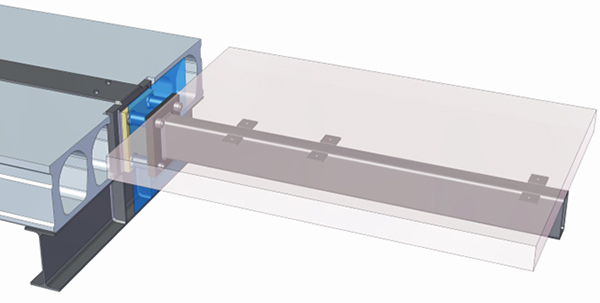

| HSQ, Deltabeam towards the end of the hollow core The picture shows an installation using a HSQ beam. |  |

| Combine the hollow core and a cantilevered BWC solution. If the hollow core is on an IPE or similar profile, we use this. Here you can also see that there is a steel band on top of the hollow core. |  |

BWC U-H |  |

Balcony for corner wall

To balconies for corner wall we recommend BWC 40 U-H

All variants of corner balconies must be calculated and checked individually! The tables in Memo 750 will NOT be able to give correct

answer in terms of deflection.

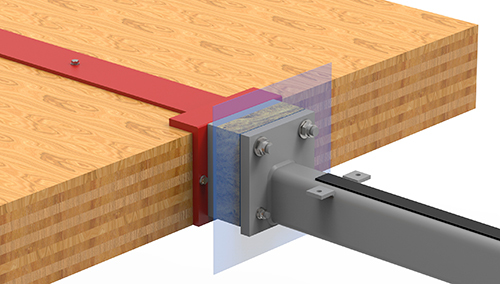

| BWC U-H in casted slabs. The unit is welded to a steel plate with horizontal reinforcement rods. When using a steel support system and hollow core, it is recommended to replace the hollow core with a reinforced deck closest to the balcony. The picture show BWC 40 U-H with welding plates in the casted slab, and a steel |  |

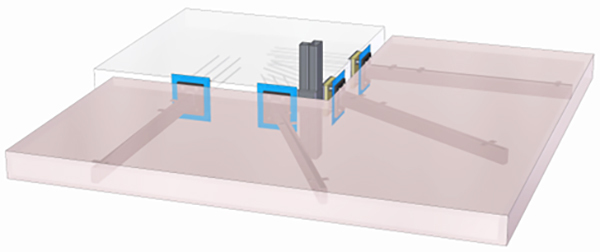

| The picture show the BWC 40 U-H system in an analysis (see Memo 755A) |  |

Capasities

| UNIT | Max. torque (kNm) | Max. shear force (kN) | Max. horizontal force (kN) |

| BWC 40 U-H | 60 | 70 | +/-20 |

Units

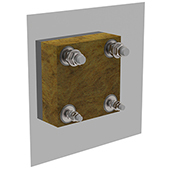

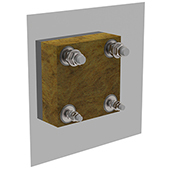

| The picture show the complete BWC 40 U-H system |  |

| BWC 40 U-H | System that is welded to a steel plate, RHS profile, U beam, HSQ, Deltabeam etc. |  |

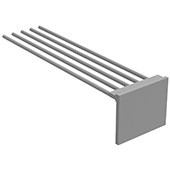

| BWC 40 Utliggere | This is the cantilevered profile (RHS, I beam or flat steel) which supports, for example, a thin concrete slab, metallic or wooden balconies. The dimension here is determined by the length and depth of the balcony, and is delivered hot-dip galvanized. |  |

| BWC 40 Plate | To be placed in casted slabs. |  |

| BWC 40 U | On special request. |  |

Brochuresfor downloading